Our Services

Plant Turnaround & Shutdown

Storage Tank Maintenance

Maintenance & Repair Services

PLANT TURNAROUND & SHUTDOWN

Services we provided:

- Total tank maintenance services that includes cleaning, blasting and painting of shell/bottom plate replacements, as well as seal replacement/installation, tank appurtenance and/or foundation repair, piping tie-ins/replacement and other related services.

- Heat exchanger maintenance including tube bundle extraction/change-out, high pressure water jet cleaning of exchanger tubes repair works and other related works.

- Cleaning or repair of columns, drums, miscellaneous unfired pressure vessels, that includes boiler open-up, inspection and other associated works during plant turnaround/shutdown.

- Overhaul and testing of Pressure Safety Valves, Block Valves and other related materials

- Overall fabrication and repair works.

- Boiler maintenance, CF Renewal & MI.

What We Do

Project planning and scheduling

Valve and RV Servicing

Blasting and Painting activities

Start-up preparation

Cold Cutting

Chemical Cleaning

Joint integrity management and Control Bolting

Mechanical activities

Manpower and Material Supply

Catalyst Changeout

High Pressure Water Jetting

Scaffolding and insulation

Inspection activities

Fabrication and Repair Work

On-site Machining and Resurfacing

Heat Exchanger Bundle Puller

Storage Tank Maintenance

Mushtari Maintenance Services have 30 years of experience in total tank maintenance which includes cleaning, blasting and painting of shell, bottom plate replacements, and seal replacement, tank appurtenance & foundation repair, piping tie-ins and specialty in fabrication works. We offer full project management of all your storage tank cleaning and maintenance needs, working to the API 653 standards and higher within the refining and petrochemical industries. Our highly-skilled and experienced employees work closely with our customers to understand their specific project requirements and develop safe, cost-effective and industry-leading solutions.

- Total tank maintenance services that includes cleaning, blasting and painting of shell/bottom plate replacements, as well as seal replacement/installation, tank appurtenance and/or foundation repair, piping tie-ins/replacement and other related services.

- Heat exchanger maintenance including tube bundle extraction/change-out, high pressure water jet cleaning of exchanger tubes repair works and other related works.

- Cleaning or repair of columns, drums, miscellaneous unfired pressure vessels, that includes boiler open-up, inspection and other associated works during plant turnaround/shutdown.

- Overhaul and testing of Pressure Safety Valves, Block Valves and other related materials

- Overall fabrication and repair works.

- Boiler maintenance, CF Renewal & MI.

Desludging

Sludge Bug technology system applied to achieve high productivity rate of heavy sludge removal

Blasting Painting

Various type of method offered sand blasting, sponge jet blasting and hydro blasting

Hydrojetting

To achieve highest quality cleanliness standard

Scaffolding

Working platform to access high location

Cleaning

Manual cleaning fir light product tank maintenance

Rim Seal Replacement

Vast experience in online and offline replacement

Hot Work (Fabrication & Repair)

Offer wide variety of scope including fabrication and major repair work work. i.e: Tank construction, repair, alteration and reconstruction

Hydrotest

To ensure the integrity of the tank after undergo major repair works

What We Do

Project planning and scheduling

Valve and RV Servicing

Blasting and Painting activities

Start-up preparation

Cold Cutting

Joint integrity management and Control Bolting

Mechanical activities

Manpower and Material Supply

High Pressure Water Jetting

Heat Exchanger Bundle Puller

Scaffolding and insulation

Inspection activities

Fabrication and Repair Work

On-site Machining and Resurfacing

Chemical Cleaning

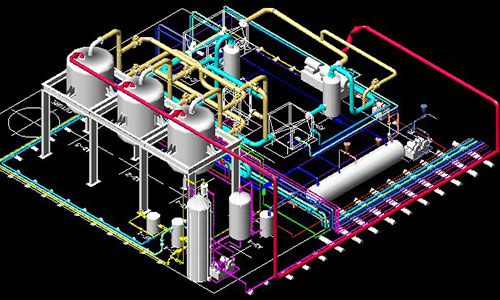

Maintenance & Repair Services

We are experienced at providing total plant maintenance services across the oil and gas and petrochemical industries. We have the processes, systems, advanced equipment and trained specialists to cope with all types of planned maintenance (PM), corrective work, pit stops, shutdowns, minor upgrades, revamps and emergencies

- Total tank maintenance services that includes cleaning, blasting and painting of shell/bottom plate replacements, as well as seal replacement/installation, tank appurtenance and/or foundation repair, piping tie-ins/replacement and other related services.

- Heat exchanger maintenance including tube bundle extraction/change-out, high pressure water jet cleaning of exchanger tubes repair works and other related works.

- Cleaning or repair of columns, drums, miscellaneous unfired pressure vessels, that includes boiler open-up, inspection and other associated works during plant turnaround/shutdown.

- Overhaul and testing of Pressure Safety Valves, Block Valves and other related materials

- Overall fabrication and repair works.

- Boiler maintenance, CF Renewal & MI.

Control Bolting (HTW / HBT)

Control bolting as per approved JIT procedure

Insulation

Insulation supply and replacement for piping, coldbox, boilers and equipment

Engineering and Design

Design piping, support structures and equipment

Hydrotest

To ensure the intergrity of the tank after undergo major repair works

Machining

Machining service i.e: resurface gasket seat, cold cutting

Lifting

Cranes and boom truck for heavy lifting

Manpower Supply

Direct hire manpower for oil and gas maintenance work

Blasting Painting

Various type of method offered including sand blasting, sponge jet blasting and hydroblasting

Hydrojetting

To achieve highest quality cleanliness standard

Scaffolding

Working platform to access high location

Hot Work (Fabrication & Repair)

Offer wide quality of scope including fabrication and major repair work. i.e: Tank contruction, repair, alteration and reconstruction

PSV Servicing

Safety valve periodically servicing